Products & Offerings

At Carbon Light, we are proud manufacturers of advanced composite products, serving the aerospace, defense, industrial and medical sectors. Our expertise lies in delivering customized solutions tailored to meet your specific requirements, setting us apart in the industry.

Drone Frames

Industry: Aerospace | Defence | Agriculture

Carbon Fiber Rollers

Industry: Printing & Packaging | Textiles

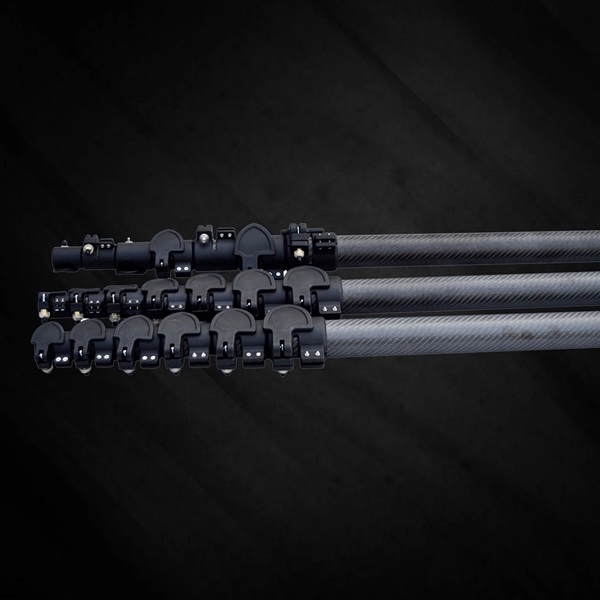

Telescopic Poles

Industry: Defence | Industrial | Agriculture

Carbon Fiber Reflectors

Industry: Defence

Composite Drive Shafts

Industry: Industrial

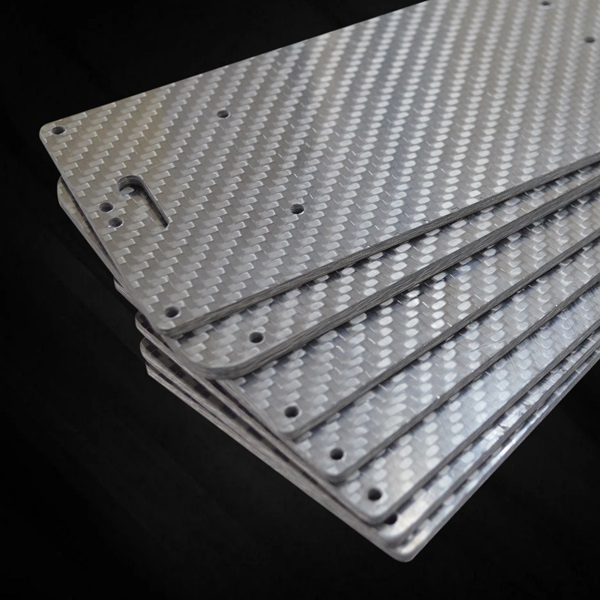

Carbon Fiber Sheets

Industry: Aerospace | Defence | Industrial

Carbon Fiber Rods

Industry: Medical | Defence | Aerospace

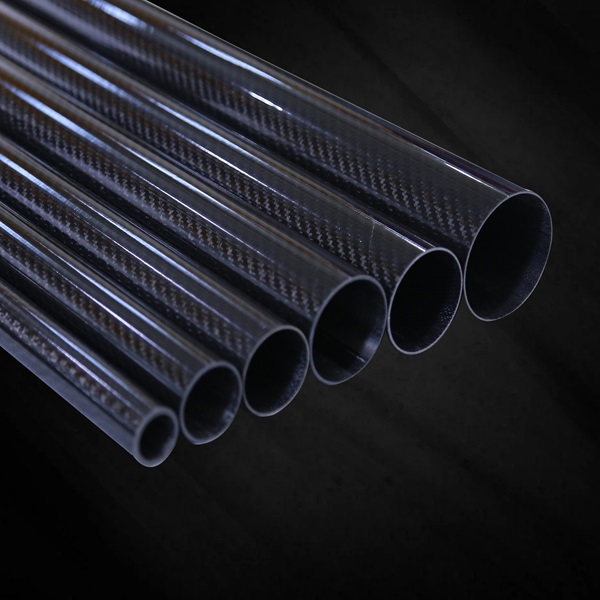

Carbon Fiber Tubes

Industry: Aerospace | Robotics | Defence